Client: ID Logistics

Product: Knowledge transfer, knowledge management, development of digital competencies, digital twin

Immersive logistics VR training: transforming workforce efficiency and safety

Connected Realities, in collaboration with ID Logistics, has redefined workforce training in the logistics industry through immersive VR technology. This cutting-edge solution enhances operational efficiency, safety, and onboarding speed by providing a risk-free, interactive learning environment. VR training remains one of the most impactful investments in virtual technologies, with proven effectiveness across industrial sectors. This collaboration demonstrates the power of immersive learning in optimizing logistics operations and shaping the future of workforce education.

Short project description

ID Logistics, a leader in the logistics and e-commerce sector, has developed an innovative VR training application in collaboration with Connected Realities. Logistics requires precision, efficiency, and safety. Traditional training methods are time-consuming and often fail to engage employees sufficiently for effective knowledge retention.

The implementation of VR training allows for a realistic simulation of operational processes, enabling both new and existing employees to engage in an interactive, practical learning experience within a safe, controlled environment. This approach helps them better understand and practice procedures tailored to the logistics industry’s specific needs. The training is designed to cater to both younger and older generations and can be conducted in multiple languages.

What need does the solution address?

High employee turnover, dynamic operational conditions, and the need for rapid onboarding drive the logistics industry to seek more effective training methods. The challenge was to develop a solution that shortens onboarding time, reduces errors, and enhances knowledge retention in a fast-paced logistics environment.

The training scenarios, developed by ID Logistics and Connected Realities, enable employees to acquire and immediately apply new knowledge in a virtual environment that serves as a digital twin of real-world workstations. The entire training is conducted using VR headsets, ensuring that operational workflows, such as package sorting lines, remain uninterrupted while training can take place anywhere. The training scenarios are available in multiple languages, significantly improving communication and accessibility for an international workforce.

Efficient package sorting leads to faster order fulfillment, improved workflow organization, and reduced errors. Well-trained warehouse employees can significantly boost logistics processes’ efficiency. By integrating virtual reality with digital twin technology, this training solution facilitates better comprehension of key organizational and ergonomic principles in an immersive, engaging way.

The challenge

Traditional training methods are time-consuming and could fail to engage employees effectively. Connected Realities was tasked with developing a mobile and intuitive training tool that could be used in a dynamic and demanding warehouse environment.

This solution combines practical skill-building with a long-term strategy to enhance the company’s image as a modern employer investing in innovative technologies that improve both work quality and efficiency.

Idea description

The VR training transports users into a realistically simulated logistics facility, where they can practice all essential work stages.

Example VR Training Scenario Includes:

- Ergonomic lifting and stacking of packages according to safety regulations.

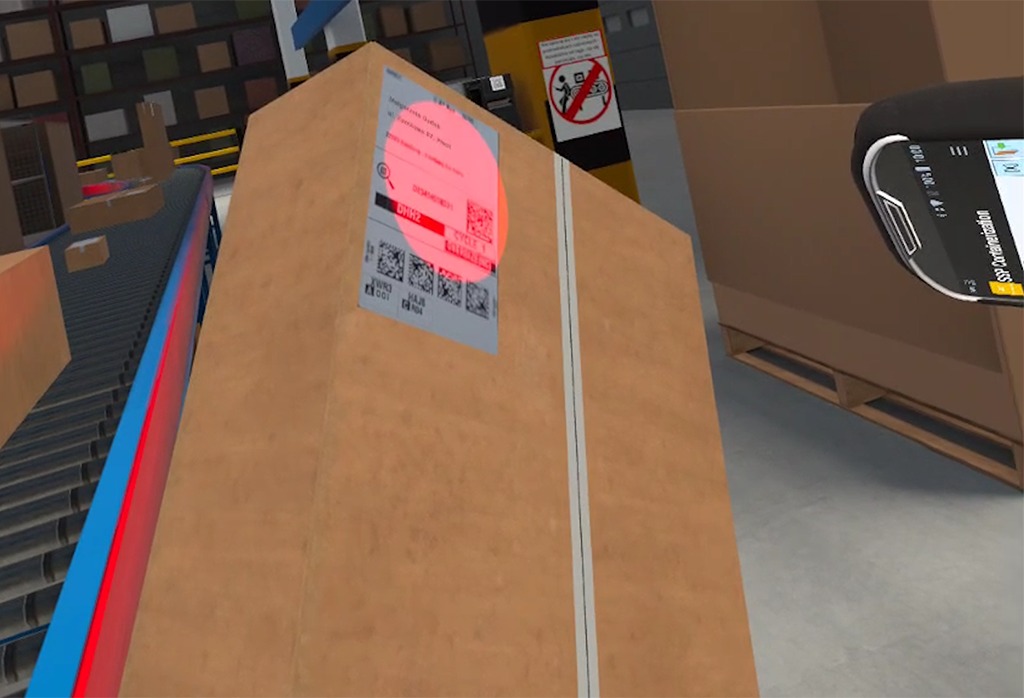

- Identifying labels and barcodes and assigning packages to the correct sorting areas.

- Responding to unexpected situations, such as damaged packages, incorrect labels, or sudden changes in shipping priorities.

The training is available in multiple languages, ensuring flexibility for an international workforce.

Implementation

The VR training program is designed to provide an immersive user experience. Using VR headsets, participants can virtually step into a logistics hub and learn through hands-on practice. The system tracks participant progress, analyzes their performance, and adjusts the difficulty level to match individual needs.

Key implementation elements:

- Realistic environment and process simulation – The VR environment accurately replicates the logistics facility’s appearance and operations.

- Interactive Scenarios – Users make decisions and learn from the consequences in a risk-free setting.

- Multilingual Module – The training is available in multiple languages to accommodate an international workforce.

- Performance Analysis – The system monitors progress and identifies areas needing further training.

Results

What Value Does the Ability to Learn Freely Without Consequences Bring to the Trainee? Implementing VR training has significantly reduced onboarding time for new employees. Operational efficiency has improved due to fewer errors and a better understanding of procedures. Employees also retain safety protocols more effectively, reducing the risk of workplace accidents. The engaging and dynamic format encourages knowledge acquisition.

Long-term benefits include:

- Faster and more effective onboarding of new employees.

- Reduction in errors in logistics processes.

- Lower costs associated with mistakes and workplace incidents.

- Standardized knowledge transfer in an international work environment.

- Higher engagement and knowledge retention due to the immersive learning format.